The all-in-one qualities of Super Spacer® have proven their worth at the Pathé Palace in Paris.

Today, warm-edge spacers fulfil many more functions than simply increasing energy efficiency and room comfort. There is an increasing demand for outstanding aesthetics, processing quality and production-related advantages.

With applications ranging from automated large-scale production and structural glazing to organic shapes and monument protection Quanex Company Edgetech claims that its flexible Super Spacer® is the ideal solution for all projects, even the most challenging ones. For example, it was used in the restoration and modernisation of the magnificent Pathé Palace in Paris, a building from the Parisian Belle Époque, by Renzo Piano Building Workshop.

The successful transformation of an iconic film venue.

For over 150 years, the building at the intersection of Boulevard des Capucines and Rue de la Chaussée d’Antin has been a cultural landmark. Originally opened in 1869 as a vaudeville theatre, it was converted into a cinema by Paramount in 1927 and later transformed into a luxurious film palace by Renzo Piano on behalf of the Pathé Group. The new Pathé Palace boasts seven state-of-the-art auditoriums with LED screens and heated, adjustable leather seats.

At the same time, the golden age of Parisian Belle Époque and widescreen cinema has been brought back to life. Instead of streaming from the comfort of your own home, an exclusive concierge service awaits. Behind the rotunda façade, characterised by three curved windows between pairs of neo-classical columns, is the Art Deco-style bar. Designed by Jacques Grange, probably the world’s most famous interior designer, it offers a breathtaking view of the vibrant theatre district in Paris’s 9th arrondissement.

“Light and transparency are very close friends.”

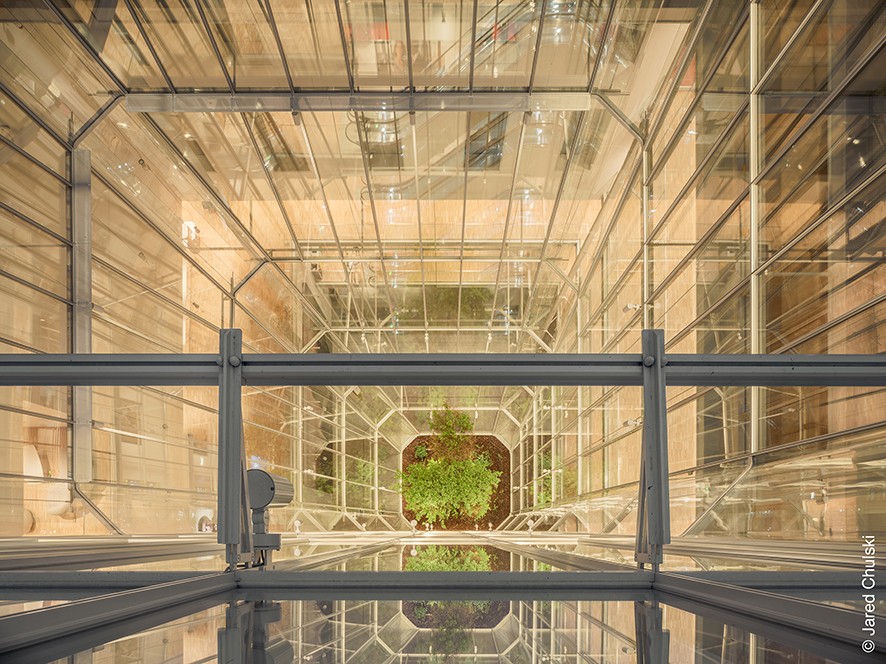

This quote by Renzo Piano encapsulates the design leitmotif of many of his buildings. The Pathé Palace was therefore completely gutted and extensively glazed at street level. The building’s transparency is intended to invite the city to enter the light-flooded atrium, ‘the piazza’. Only the striking dome, rotunda and natural stone façade from the Belle Époque period were reconstructed. In accordance with official specifications, some interior elements such as the grooved marble, stucco work and cast-iron banisters also had to be integrated into the redesign.

An inverted glass pyramid dominates the 300-square-metre ‘piazza’ behind the entrance area. Measuring just 45 square metres at its base, this elegant glass and steel structure expands to a width of 29 metres, creating a clear opening of 154 square metres and allowing natural light to flood into the building five storeys deep. The 1,200-square-metre, 150-tonne interior façade is suspended. To hold and stabilise the filigree mullion-transom system for the glazing, façade builder Josef Gartner constructed a light grey, painted steel structure.

Super Spacer®: flexible for difficult geometries, light grey for transparency

Gartner and the renowned bending specialists at Döring Glass developed a technically complex insulating glass construction for the corners. The 28 double cylindrically curved rectangular panes ranged in dimension from 1638 x 5546 mm to 1663 x 3440 mm. The 44- and 46-degree bends each form a 90-degree corner with a flat section in between, followed by a short straight section after the bends.

The radii range from 100 to 150 millimetres, depending on the bend. The inner and outer panes are made of 12 mm laminated safety glass composed of extra-clear DIAMANT® float glass and PVB film. A 10-millimetre-wide Super Spacer® TriSeal™ Premium Plus spacer in ‘light grey’ was used in the space between the panes. The architects had specified a grey spacer for the entire glass pyramid. As it virtually merges with the glass, the spacer plays its part in realising Renzo Piano’s vision of an atmosphere of light, airiness and transparency.

Martin Lenz, Sales Manager at Döring Glass, emphasises: ‘Super Spacer TriSeal Premium is ideal for difficult geometries as it can adapt flexibly to any contour. Fortunately, Edgetech allows for individual colour selection, so we were able to meet all the technical specifications without any problems.’

Joachim Stoss, Edgetech Europe’s Vice President of International Sales, adds: ‘We have a long-standing partnership with Döring Glass. We are delighted that our Super Spacer enables us to fulfil even the most demanding architectural requirements in terms of edge seal aesthetics. Curved glass is finding more and more applications in architecture as it enables the creation of fluid, organic shapes. The fine art of glass bending and the production of free-form glass are integral to parametrically planned building envelopes.”

Super Spacer® flexible spacers are ideal for curved glass, as they can adapt to complex curves and radii. However, they also offer advantages for flat glazing. Their elasticity reduces stress in the edge seal and distributes forces evenly, thereby minimising the risk of breakage. During production, they facilitate precise application, even with tight radii. They also absorb hardly any climatic loads, which relieves the edge seal even further. They ensure maximum accuracy and parallelism of the panes, as well as clean edges, with both automated and manual processing, particularly with large format insulating glass elements.

“Super Spacer has several key properties that make it ideal for clean corner formation in the edge seal. Applying it from the roll enables precise 45-degree transitions. Thanks to its elasticity, the silicone structural foam can adapt better to the corners of the glass, ensuring an even surface without the risk of bubbles forming,” explains Christoph Rubel, technology expert at Edgetech.

A view of the Boulevard des Capucines as seen through double-curved XL glasses.

For the Pathé Palace’s rotunda façade, Döring combined and realised two further manufacturing challenges with Super Spacer®: large format curved double glazing, with the largest piece measuring 963 by 4,811 millimetres and comprising three different glass structures.

“Only white glass was used for the 24 curved insulating glazing units on the exterior of the building. In some cases, this was combined with ECLAZ and ECLAZ ONE coatings to maximise transparency and light transmission while ensuring optimal thermal insulation,” says Lenz.

The curved glass underwent various long-term tests on ageing behaviour, dew point and gas concentration over a period of more than six months before installation and acceptance by the client, in order to prove the performance and reliability of the spacer.

‘In a constantly changing world, adaptability is the key to success,’ explains Joachim Stoss of Edgetech. ‘Super Spacer provides our customers with the means to react to current market requirements and proactively shape future trends.’